Origin of Kate Valley Landfill

Five District Councils: Ashburton, Selwyn, Waimakariri, Hurunui and Christchurch City Council got together and decided they needed to close down 52 unsafe old-style rubbish dumps. They needed to build a modern safe landfill for their 500,000 residents. They chose Kate Valley, 70 kilometres north of Christchurch. The total site is 1,000 hectares, of which 37 hectares will be used as a landfill. All features of the design and operation of the new landfill meet international best standards. The Kate Valley Landfill was opened on the ninth of June 2005.

State-of-the-art liner

Rain water seeping down through the rubbish dissolves poisons, creating a liquid called leachate. This leachate is toxic and must never go into the groundwater. To stop this from happening, a very special liner is laid on the ground before the rubbish is added to the landfill. This liner is made up of three layers of different materials.

Leachate collects on the liner. It then flows downhill and is pumped into storage tanks for treatment.

Surface water that runs off the landfill site (not leachate) flows into a separate system and is collected in a pond 1km downstream of the landfill. This water is carefully monitored for quality at different locations and used for dust control.

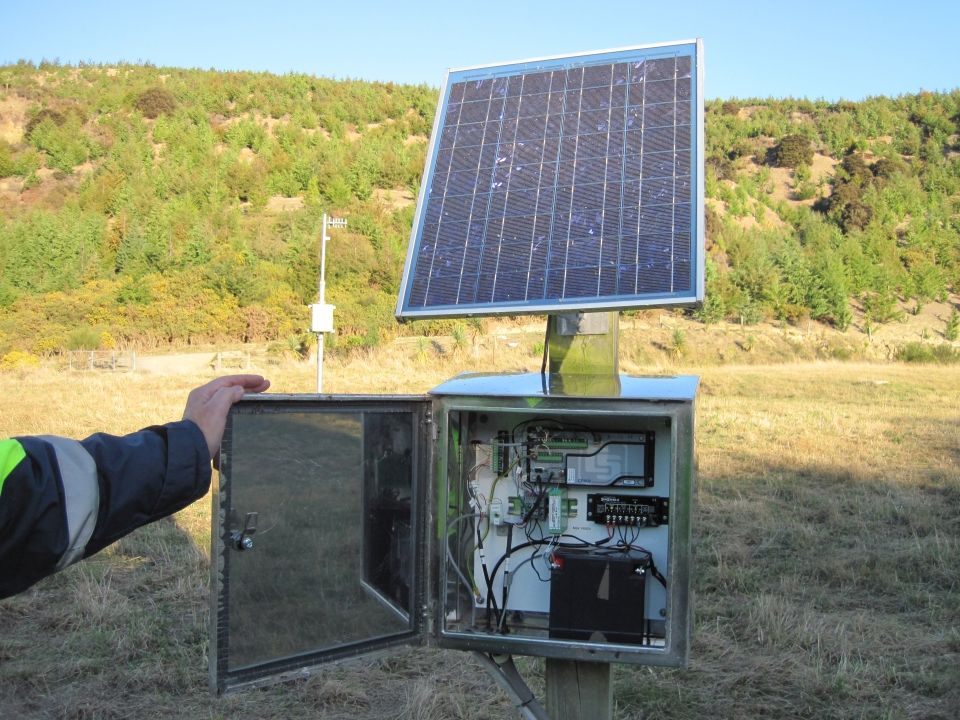

(Extensive) monitoring and testing

Remote sensors collect all sorts of information about water, downstream of the landfill. This information is sent by coded signals on a computer based wireless system called telemetry.

Modern machinery

The landfill uses a new generation Caterpillar 836H Compactor which is used to compact waste as densely as possible. A fleet of truck and trailer units haul waste from transfer stations to the landfill. Each truck has a range of safety features, including exhaust emissions controls to meet the strictest emissions standard in the world.

Trucks with real-time cameras and GPS

Canterbury Waste Services was one of the first companies to use ‘Drive-Cam’: special cameras inside the trucks that record through the front windscreen. The cameras also record driver behaviour and are used to improve safety on the road.

Other cameras around the truck record what is happening on the road.

All trucks are fitted with GPS. This means that the location of the truck as well as its speed is known at all times.

All trucks are fitted with hands-free mobile phones and radio telephone.

Because the trucks are large and travel on busy roads with dangerous cargo the drivers need to be highly qualified and closely assessed. All drivers undergo testing to make sure they have the right skills and knowledge, abilities, attitudes and personality traits to be responsible and safe drivers.

Methane capture for electricity generation (x4)

As rubbish decomposes it produces a gas called methane. Methane is an odourless, flammable gas that can be highly explosive. At Kate Valley 51 wells constructed or drilled down into the rubbish collect the gas. It is then piped to a generation plant that makes electricity. Four 1 Mega Watt gas engine generators send 4 Mega Watts of electricity into the national grid.

Safety is #1

Safety is the number one priority at the Kate Valley landfill. They are very proud to say they are up to 2,000 days (how many years is that?) without any ‘loss time days’. That means there have been no staff away for more than one day because of injury or illness that happened at work.

There is also a special programme at Kate Valley called the Opportunity for Improvement. As human beings, we all make mistakes. Our own mistakes, and the mistakes of others, can be used to help improve ourselves every day. At Kate Valley every incident is used as a way for everyone to learn how to do their job more safely. The staff make suggestions and improvements that change the way people do their jobs. The Opportunity for Improvement programme has a no-blame safety culture.

Peer-reviewed engineering

Is Kate Valley doing the best it can? The landfill operations and procedures are peer reviewed every three months by a group that are experts in their field. They check that the landfill construction and environmental controls are following international best practice. The report is publically available and recommendations are used to make changes to the way the landfill operates.