You can contact LEARNZ, part of CORE Education, at:

Postal Address:

PO Box 13 678,

Christchurch 8141,

New Zealand

It was great to finally see the progress that has been made on the Memorial Park and underpass since the first Memorial Park field trip last November. Work has certainly been going at a fast pace – then again it has to if the Memorial Park Alliance is to meet their deadline for ANZAC Day 2015.

Cole Meiring took you through the tunnel that has been constructed so far. Over 80 metres of the underpass has been covered, so there is a little less than 40 metres of cover to go. The work site was barely recognizable since Memorial Park 1. If you have a look at Shelley’s diaries from that field trip you will be able to make some comparisons between then and now. Basically the site has gone from a lot of dirt, diggers and temporary retaining walls to something that now resembles a concrete tunnel. The project is really taking shape and is no doubt on track to have the tunnel operational by the end of this year.

Apart from lots of steel reinforcement and concrete, one thing that was very noticeable was the amount of scaffolding you could see inside the tunnel. You heard from site engineer Russell Scoones about this support structure (also known as falsework) that is put up for each of the concrete roof spans that are poured on site. This scaffolding takes almost one month to prepare before the concrete can be poured. The falsework is then shifted out from underneath the roof span about a week later when the concrete has had time to cure.

There were some other interesting structures called formworks that have to be constructed for some of the on-site concrete pours. These formworks act as a mould for the concrete to be poured into. Have you ever made ice-blocks at home? You have plastic moulds that you pour juice into before putting into the freezer to set. When you take the ice-block out of the mould it has the shape of that mould. This is the same sort of job that formworks do.

Russell showed you a piece of formwork made for a part of the underpass wall. At certain parts of the wall there are different dimensions that do not allow pre-made steel formworks to be used to pour concrete into. In these cases the team have to actually build the formworks to suit the shape of that particular part of the tunnel wall. It sure is amazing just how much work goes into building structures that are only temporary. Nonetheless they are very important structures and there is little room for error – especially when you are dealing with tonnes of concrete!

This tunnel is being built extremely strong. The 800 millimetre thick walls, floor and roof are being formed from steel-reinforced concrete. Specialist steel workers have been installing a dense network of steel reinforcing in the trench. Concrete is then poured into the reinforcing. The finished product will be strong enough to withstand a 1-in-2500 year earthquake. It will also be waterproof. The tunnel sits below the water table so the outside of the walls have a special membrane that seals the concrete to prevent water from leaking through it.

It was soon time for lunch, much to the relief of the starving ambassadors! It was also time for the first of our audioconferences this week. Big thanks to Rosebank School and St Peter’s School for your excellent questions – you certainly kept our experts on their toes! If you were unable to hear these audioconferences live you can go to Audioconference Recordings to listen at a later date.

After the audioconferences you met Geotechnical Engineer Sam Glue. Sam explained how the underpass piles work to give it further strength. Part of the tunnel sits on soil that is liquefiable in an earthquake. Without the piles the underpass would basically become buoyant during a large earthquake event and float up with the liquefaction. So the piles are like anchors. They are attached to the tunnel floor and go down a maximum of 30 metres through the soil and into the bedrock. Once in the bedrock they are anchored firmly in place. The concrete piles are designed with a bell-shape at the bottom. Testing found that straight piles would not hold as tightly in the soil as required for the underpass. By adding a bell-shape, the engineers have been able to achieve their design requirements.

The final part of the day was spent looking at how the Memorial Park and Underpass project can be used to provide real-life examples of the technology curriculum. Cole Meiring spoke about technological products and the relationship between the concrete used for the project and its performance properties. He also gave a broad outline of technological practice, specifically looking at brief development, planning, and outcome and evaluation. Take a look at these two videos for further insight.

It has been a fascinating day on the Memorial Park underpass construction site. The scale of this project is immense, and it is impressive to see how well the project is meeting its objectives.

I look forward to you joining us again tomorrow. Be warned, you may need your raincoat!

The construction site is starting to take shape. Compare this picture with one from the first field trip. Image: LEARNZ

The underpass roof looking stylish in black! Can you see the brackets? What do you suppose they will be used for? Image: LEARNZ.

The scaffolding 'falsework' holding up the concrete roof while it dries. About how long does it take for the concrete to dry enough for the falsework to be removed? Image: LEARNZ.

This picture gives you a good idea of the thickness of a roof span. Why has steel reinforcing been left sticking out of the wall? Image: LEARNZ.

Here you can see formworks made out of timber. Can you see the part of the wall on which it will be used when the concrete is poured? Image: LEARNZ.

These are steel formworks being taken off the side of a wall where the concrete is now dry. Why are the workers water-blasting them? Image: LEARNZ.

The outside of the walls have a special black waterproof covering. The white covering is another protection layer - what do you think this layer will protect the wall from? Image: LEARNZ

Some of the network of steel reinforcing on part of the tunnel floor still to be completed. How does the steel make the concrete stronger? Image: LEARNZ.

Russell Scoones was your expert during today's first audioconference. What is Russell's job title? Image: LEARNZ.

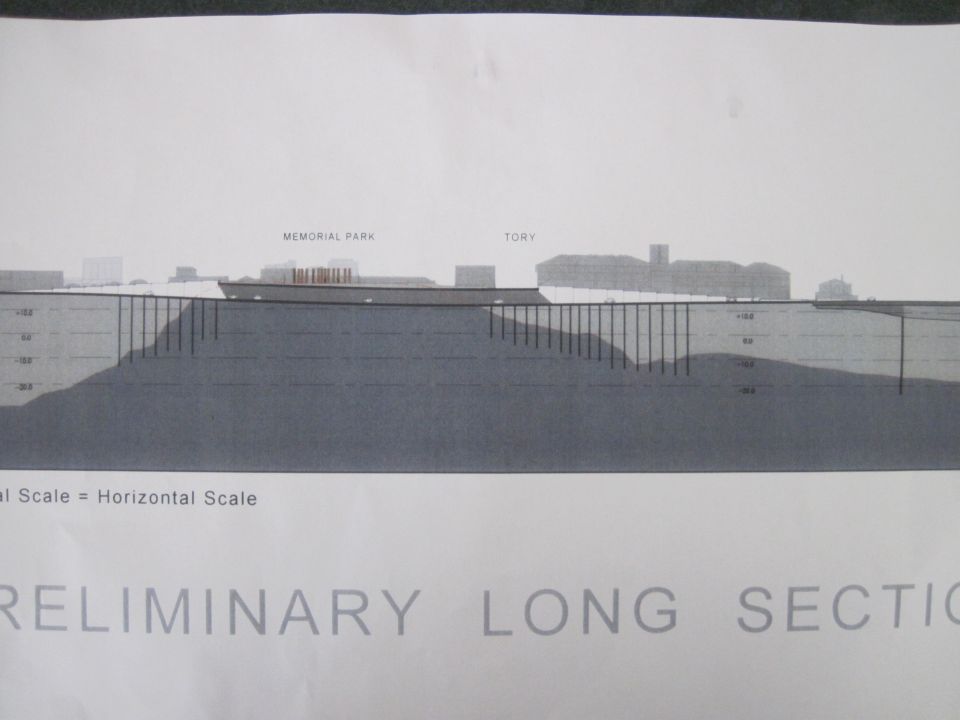

This graphic shows you where the piles are placed on the underpass floor. How do these piles add strength to the underpass? Image: LEARNZ.