You can contact LEARNZ, part of CORE Education, at:

Postal Address:

PO Box 13 678,

Christchurch 8141,

New Zealand

Kia ora koutou,

Today was all about mussels and I don’t mean the ones you flex. New Zealand’s green lipped mussels are found nowhere else in the world and exports of these delicious little shellfish are worth millions of dollars. To discover more about this curious creature and aquaculture you headed out to SPATNZ.

Shellfish Production and Technology

SPATNZ stands for Shellfish Production and Technology New Zealand Limited and they are working with the Ministry for Primary Industries and Sanford, New Zealand’s largest seafood company. This partnership aims to improve mussel aquaculture and produce better mussels. You met Sarah who is the research and development team leader at SPATNZ. Sarah showed you around the mussel hatchery and answered questions from Shotover Primary School and Havelock North High School. These students had some interesting questions including how mussels could be affected by climate change. You can find out more by listening to the recorded web conference.

The secret life of mussels

SPATNZ spawn mussels at the hatchery each month. This week staff are focusing on delivering spat (baby mussels) to mussel farms in Pelorus Sound so you didn't get to see mussels spawning. Scientists have managed to unlock the secret life of mussels and through trial and error have discovered how to breed mussels in captivity. Sarah explained that it has taken a lot of hard work to figure out the best process. They have tried all sorts of methods to encourage mussels to breed, such as different lighting, water temperatures and sounds. The perfect combination of light, temperature and small vibrations seems to work and now SPATNZ can produce billions of mussel eggs each month and the great news is that these are growing into strong, faster growing and more consistent mussels.

Why breed mussels

You may be wondering why baby mussels need to be produced in a hatchery when they can grow in the wild. For years mussel farms have used wild spat but it can be affected by all sorts of things, such as weather. Wild spat differs in quantity and quality, and mussel farmers never know when it will be available. One of the advantages of hatchery spat is that it can be supplied regularly and in sufficient quantities. Sarah talked about how much more sustainable this will make the mussel industry and how using only the best mussels as parents will lead to better baby mussels.

Raising mussel larvae

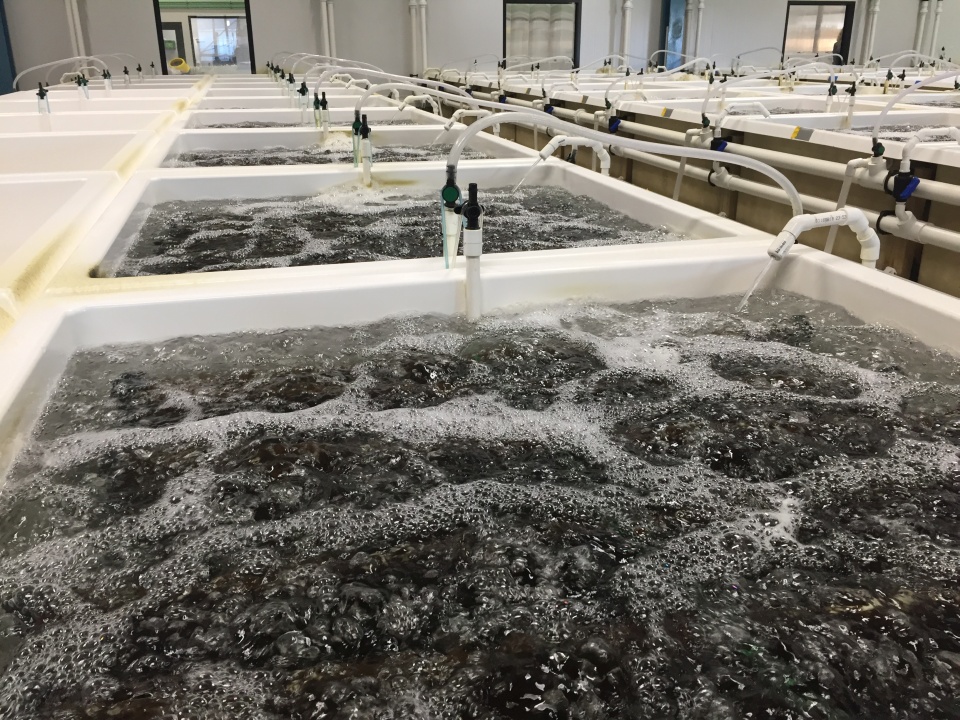

It was incredible to see just how many mussels can be produced at the hatchery. You saw huge tanks used to grow mussels from their swimming larval stage through to their settling stage. Mussel larvae are tiny and can only be seen under a microscope. The tanks holding mussel larvae were brown in colour as millions of mussel larvae gather in what looks like a brown slurry. Hannah showed you how mussel larvae are screened every two days to maintain quality. This is done by filtering the tanks of mussel larvae through very fine sieves to remove the undersized mussels. I hadn’t realised that mussels have a swimming larval stage and it was neat watching them under the microscope as the zoomed around.

Food for filter feeders

Mussels are filter feeders meaning all their food comes from the water that they filter. Mussels are like a small living pump. They draw in water from one side and they pump it out the other side, but in between they have filters which work as gills, extracting oxygen out of the water and food. Mussels need a lot of phytoplankton (algae) to feed on. Ellie showed you where the hatchery grows this food. Huge bags of brown and green liquid hung in the algae room.

The hatchery gets algal cells from overseas where they are extracted from seawater. These cells are then grown and fed to the mussel spat. The algal room is kept at a cosy 25 degrees Celsius and well-lit to help the algae grow. The water used to grow the algae must be kept very clean and like all the water entering and leaving the hatchery it is treated to remove any bacteria. Ellie explained that hygiene in the hatchery is essential and every time you entered a different area you had to use hand sanitiser and walk through a water bath to clean your gumboots. You can find out more in the video.

From the hatchery to the farm to your plate

After about three weeks the mussel larvae change and lose their swimming organs. This is when the young mussels need somewhere to settle. Sarah showed you the settlement-tanks that are used to grow the mussels after settlement. The spat are able to hang on with a thread that they secrete. At this stage the spat are visible as tiny white dots. Watch the video to find out more. It takes about 7-8 weeks from spawning to spat that are large enough to take out to the mussel farms and within two years these mussels will be ready to eat.

It has been fascinating to see how science and technology are helping the aquaculture industry and tomorrow you will see more kiwi ingenuity at a very different kind of farm.

See you early in the morning ready to milk sheep.

Shelley the LEARNZ field trip teacher.

You began the day at SPATNZ mussel hatchery in Nelson. What does SPATNZ stand for? Image: LEARNZ.

Sarah and Shelley talk to Shotover Primary School and Havelock North High School during the first web conference. Image: LEARNZ.

Hannah counts the number of mussel spat in a water sample. How do you think this number can be used to work out the number of spat in the tank? Image: LEARNZ.

Ellie shows Shelley where algae is grown to feed the mussel spat. Image: LEARNZ.

Mussels are grown in these settlement tanks for about four weeks before they are ready to send to the mussel farm. Image: LEARNZ.